Dick Elsman is a BIM Automation Engineer at Infranea. He tells us about his work on Belgium’s building site of the century: Antwerp’s Oosterweel link. We take a look at the daily activities in BIM Automation. We learn about the great advantages, but also the challenges. He tells us about what motivates him in his job. Finally, Dick gives some tips to candidates wishing to follow in his footsteps.

What does a BIM Automation Engineer do?

It appears that Dick’s main ambition is to make life easier for the designers. He makes sure that they can always work efficiently and consistently in generating identical output. Dick explains that BIM Automation is about automating manual design tasks that occur more than once. When an Automation Engineer does a good job, such automation saves huge amounts of time and money before, during and after the building work.

Thanks to BIM automation, the BIM Engineer can do 80% of the work in 20% of the time.

Dick Elsman, BIM Automation Engineer

What is the Oosterweel link project?

The Oosterweel link will complete the Antwerp ring road between Linkeroever and the existing R1 at Merksem. The project should also improve the quality of life in the surrounding districts by taking some of the existing and new ring road underground. The project is divided into different sub-projects, whereby Infranea is being tasked with the sections Scheldt tunnel Bouwdok and Rechteroever 3B. For this project, Infranea has been subcontracted by the Temporary Association (TA) ROCO (“RechterOever COmpleet”), as an association of the Belgian construction groups Besix, BAM, DEME and Jan De Nul, Cordeel, Denys, Franki, Van Laere and Van Wellen. This sub-project was awarded to TA ROCO by the commissioning client Lantis at the end of last year, following a tender. Infranea is currently working on the project with a team of twelve digital engineers.

Read more here about what Infranea is doing in another sub-project in the Oosterweel link: https://infranea.com/en/project/scheldetunnel-oosterweelverbinding/

Are you feeling the impact of the corona measures on the project?

“The biggest challenge in the actual organisation is the communication,” says Dick. In total, about 120 people are working for the TA ROCO. That naturally takes a lot of organisation. “The corona pandemic makes collaboration a little more difficult. We would normally sit together in the office for discussions and to search for solutions. All of that takes longer, now that we are working from home. Digitisation does help us to continue our project preparations remotely.”

What are the characteristics of a good BIM Automation Engineer?

“To start with, you should not be afraid of exploring unknown territory,” confirms Dick. “Nothing is set in stone when a new project begins. That’s when we determine on the drawing board how the processes will work and consider how to automate as many tasks as possible.” Dick explains that it’s not simply a matter of having smart automation or an intelligent tool. It must also be feasible and effectively used! In fact, putting things into practice is also the greatest challenge, in his opinion. It’s important to keep solutions as simple as possible. To use Dick’s words: “achieving as much as possible with as few buttons as possible.”

If I can save two people two weeks’ work with a solution, then I’ve already recovered that month.

Dick Elsman, BIM Automation Engineer

What is your specific work?

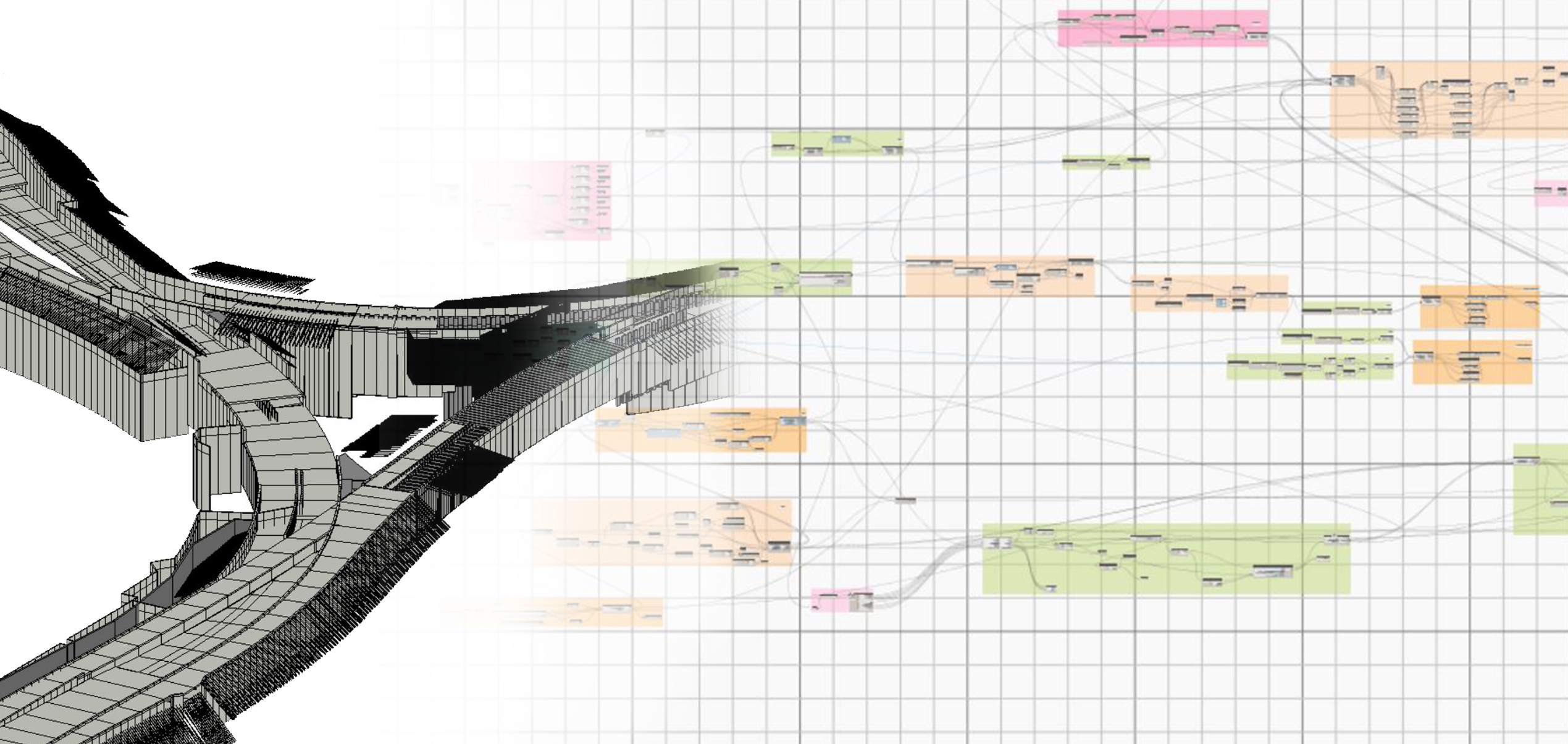

Dick makes scripts, parametric 3D objects (“digital lego blocks”) and templates. So specifically it’s a matter of modelling those “lego blocks” and making scripts to install them in a model. “Using the scripts we can build models faster and generate output from them,” says Dick.

“Above all, I see myself as an advisor,” he adds. “Everything starts with the question ‘why?’. First, you have to understand the real need or question. In essence, it’s about taking the logic from someone’s head and making a new model for it,” explains Dick. Another challenge in a large organisation is choosing the right parties to sit down with. That’s the process analysis that always precedes the modelling phase. “Also, the way in which we script and model must match the intended construction method.”

After the analysis phase comes the modelling using a ‘proof of concept’. “That’s also a matter of teamwork, to ensure that we make the relevant connections between the various disciplines. A nice example of this is the 5D database we designed, in which we connect the modelling to the planning, and finally also the cost calculation.”

Dick applies SCRUM techniques, such as short meetings, sprints with short deadlines and focus on specific actions.

It’s not enough to simply know the tools. BIM Automation is just as much a people business in which you need to get people working together.

Dick Elsman, BIM Automation Engineer

When did you start on the Oosterweel link?

Dick explains that his work already began two years ago during the tender phase; so, long before specific results were visible. “A project of this size cannot be managed in 2D, because of the great complexity,” explains Dick. So, it means innovating as soon as possible and showing the advantages of BIM in future project organisation right from the very start.

What do you enjoy about your work as a BIM Automation Engineer?

“You can be very creative,” confirms Dick. He thinks it’s exciting to keep looking a step ahead and to question everything. “I compare it with chess.” The approach pays off. Dick shares an example of how designers generate a tunnel in four days, rather than the month it would have taken without BIM automation. Dick sees another benefit in the fact that his role is not tied to a single project, but instead he supports the entire BIM team and therefore the complete project organisation.

He also says that his work is very varied and that he can organise his work to suit him within certain limits. “I don’t spend the entire day in front of a computer screen, but am frequently found in front of flip charts or brainstorming with others in our ‘inventors’ corner’ (laughs).”

As a BIM Automation Engineer, you can think up creative solutions that are also actually put into practice. That’s satisfying.

Dick Elsman, BIM Automation Engineer

What is the future of BIM automation?

According to Dick, “A huge number of applications can already do a huge amount. The key lies in making all that information available faster and better.” That’s important because the time pressure is growing. The information quality, logical connections and model make the difference, in his opinion. As an example, he mentions a solution that he co-developed, to draw objects without actually doing the drawing yourself, so directly in the model. That saves considerable time and allows traceable quality of output.

Data management will play an increasingly essential role in building projects, which just grow ever broader and more complex. Dick predicts that BIM automation will end up becoming a mandatory ISO standard in large building projects.

What is your advice for students wishing to become a BIM Automation Engineer?

Quite simple, if you ask Dick: “Stick to the software you’re familiar with and see how you can create smart routines. Make the little things easier and understand how information travels from a to b.” Students normally have a licence for Autodesk software.

Based on his experience, Dick also recommends finding a student job which is linked to what you want to do later. “I worked for more than five years as an assistant advisor in my father’s company. I had to make dashboards for clients, literally using different sources of data to provide the user with high-quality steering information. This meant continuous rethinking, communicating with clients and being creative in the search for solutions for the end user. I still apply that knowledge in my daily work. Summer jobs or apprenticeships with contractors or an engineering office are important in understanding exactly what design is all about. “You’ll be better at putting yourself in someone else’s shoes,” confirms Dick.

I’ve been active in the scouts ever since I was young. It taught me to be creative in thinking up solutions and communication, and to take responsibility. There’s no better place to learn how to see someone else’s perspective than when you’re leading a group of children.

Dick Elsman, BIM Automation Engineer

Do you have a passion for Digital Engineering? Visit our Jobs page and who knows, we may soon be colleagues!

Ten advantages of BIM automation engineering:

- Eliminating repetitive and time-consuming design, modelling and drawing tasks.

- Increased productivity and streamlining project milestones with programming software such as Python and .Net, and design software from Autodesk and Bentley.

- Improved project results with better accuracy and quality.

- Optimisation of costs and time thanks to automation.

- Less human error caused by manual modelling.

- Automation of tedious tasks, allowing engineers to focus on the real challenges.

- Supporting a uniform and high-quality interdisciplinary and multidisciplinary exchange of information.

- Better connection of technical aspects to business processes.

- Better quality assurance of the whole project by improving guarantee in uniformity of models, information and output.

- Working together to automate BIM processes, in order to achieve optimised design and building management processes with details about phasing, planning, cost calculation and detailing in complete projects.

23/03/2021